- 1555 Shanghai Road, Economic and Technological Development Zone, Suqian City, Jiangsu Province

- sales@yaret.com.cn

- +86 0527-80516888

Aluminum honeycomb panels from the best manufacturer & wholesaler yaret. yaret provides trustworthy aluminum honeycomb panels ,& owns a long experience, providing top aluminum honeycomb panels.

Aluminum honeycomb panels from the best manufacturer & wholesaler yaret. yaret provides trustworthy aluminum honeycomb panels ,& owns a long experience, providing top aluminum honeycomb panels.

Get your hands on Yaret’s Exceptional aluminum honeycomb panels. Consider Yaret for the best aluminum honeycomb panels if you’re in the market for aluminum honeycomb panels.

Customers hailing from various countries benefit from our top-notch aluminum honeycomb panels.

Our production facilities produce top-notch, long-lasting, and low-maintenance flawless. Explore our website for additional details.

Covering the entire process from raw material procurement, production and manufacturing to sales and service

Make production processes transparent, ensure quality control, information traceability, and enhance customer trust

With its excellent quality, innovative design and wide range of applications, it has won high recognition from the market and trust from customers.

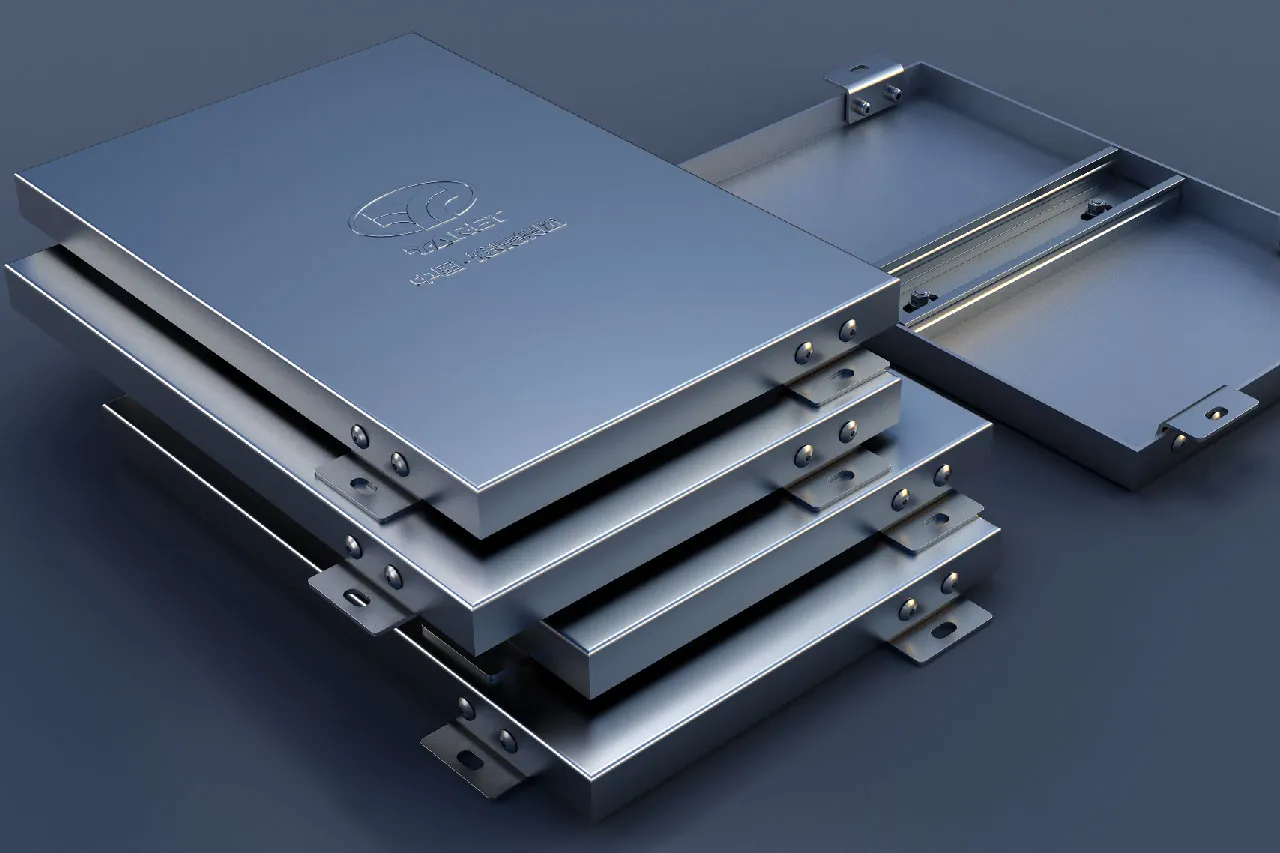

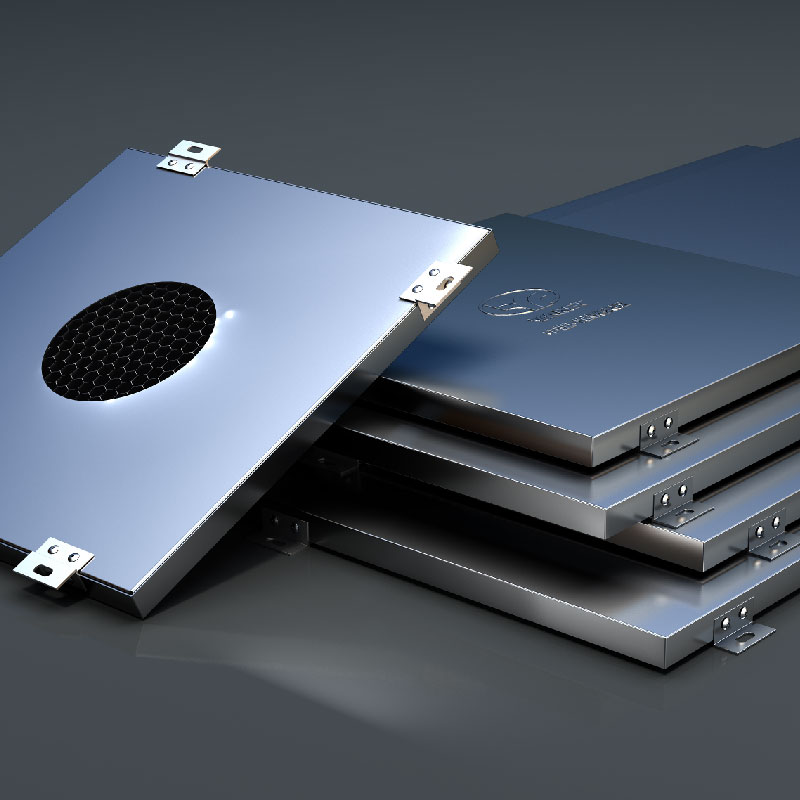

Aluminum honeycomb panels are lightweight, composite materials made of two thin layers of aluminum enclosing a core of honeycomb-structured aluminum. They offer high strength-to-weight ratios and are commonly used in aerospace, automotive, and architectural applications.

The advantages include excellent strength-to-weight ratios, resistance to corrosion, sound insulation, thermal insulation, and ease of installation. They are also environmentally friendly and can be recycled.

Aluminum honeycomb panels are typically used in various applications such as aircraft interiors, wall cladding, flooring, transportation vehicles, and in the construction of modular buildings.

Aluminum honeycomb panels are manufactured by bonding two outer aluminum sheets to a honeycomb core made from aluminum, using adhesives and processes that ensure durability and structural integrity. The panels can be customized in terms of size, thickness, and surface finish.

Yaret combines expertise in aluminum honeycomb panels with practical solutions, empowering you to navigate this exciting field.

In recent years, our organization encourages creative thinking and innovative technologies, professionalism is at the core of our success. With our cutting-edge production facilities, we assure the production of high-quality goods, we are open to discuss on product improvements and customization is possible we ensure that every product meets the criteria for professional certification. Now, with the social and economic pace, we’ve got decided to reach a broader audience. We supply our aluminum honeycomb panels worldwide, with markets including South Asia, North Africa, United States, Western Europe, etc. Good quality would be the key factor to the company to stand out from other competitors, innovation is our soul and spirit, customers’ satisfaction is our future! You are most welcome to come to China, to our city and our factory! Feel free to contact us for free quotes and any question you have. Yaret is dedicated into the market to providing premium aluminum honeycomb panels and service to global customers. We are looking forward to cooperating with you and providing our best services for you, as well as our aluminum honeycomb panels, Brushed Finish ACP,PVDF Coating ACP.

Aluminum honeycomb panels are advanced composite materials renowned for their exceptional strength-to-weight ratio, durability, and versatility. Composed of a lightweight honeycomb core sandwiched between two aluminum facings, these panels exhibit remarkable structural integrity while minimizing overall mass. Their inherent properties make them suitable for a wide range of applications, including aerospace, automotive, architectural, and marine industries. Additionally, aluminum honeycomb panels offer superior thermal insulation, sound absorption, and resistance to environmental factors, making them a preferred choice for modern engineering solutions. As a result, they facilitate rapid prototyping and design iterations, accelerating the development process in various fields of innovation.