- 1555 Shanghai Road, Economic and Technological Development Zone, Suqian City, Jiangsu Province

- sales@yaret.com.cn

- +86 0527-80516888

Top-quality wholesale aluminum plastic panels from yaret | free samples search yaret, who provides innovative aluminum plastic panels. we devote to aluminum plastic panels market for several yrs.

Top-quality wholesale aluminum plastic panels from yaret | free samples search yaret, who provides innovative aluminum plastic panels. we devote to aluminum plastic panels market for several yrs.

Yaret brings you an impressive array of High-quality aluminum plastic panels. Trust aluminum plastic panels for high-quality Yaret. We have the best aluminum plastic panels.

Our satisfying aluminum plastic panels have a global presence, satisfying customers worldwide.

Trust in the quality of our production unique, known for their durability and ease of maintenance. Discover more on our website.

Using high-quality raw materials and combining advanced production technology.

Customer-oriented, pursuit of excellence, and meeting diverse needs.

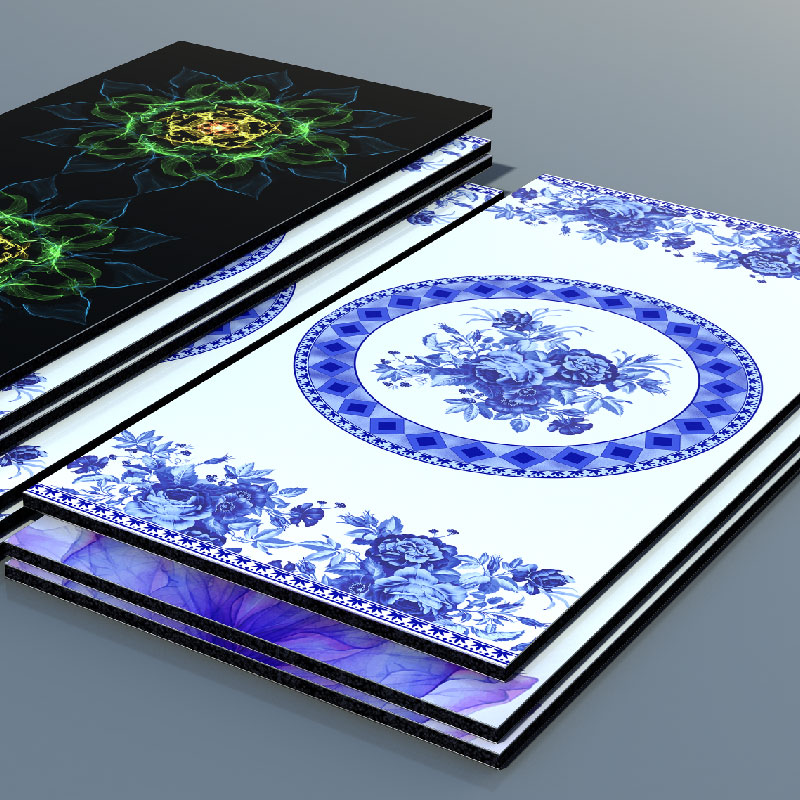

With its excellent quality, innovative design and wide range of applications, it has won high recognition from the market and trust from customers.

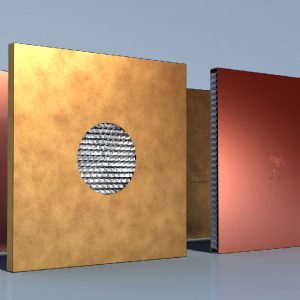

Aluminum plastic panels are composite materials made of two thin layers of aluminum enclosing a non-aluminum core, often made of polyethylene, which provides insulation and durability while being lightweight.

The advantages include their lightweight nature, excellent durability, resistance to corrosion, ease of maintenance, and aesthetic versatility, making them ideal for various applications in construction and signage.

They are commonly used as cladding for buildings, interior wall panels, signage, and in facades due to their ability to enhance both the structural integrity and visual appeal of a building.

Yes, aluminum plastic panels can be recycled, and many manufacturers encourage recycling to reduce environmental impact, although the recycling process can be more complex than that for pure aluminum.

Discover how Yaret’s commitment to excellence enriches the landscape of aluminum plastic panels for all enthusiasts.

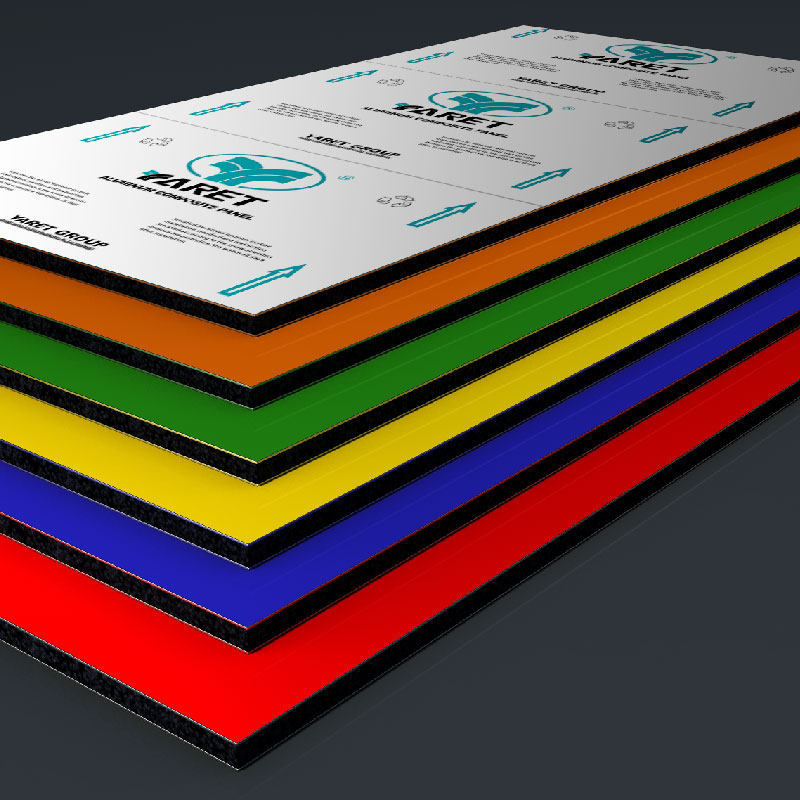

We are looking forward to cooperating with you and providing our best services for you, as well as our aluminum plastic panels, Brushed Finish ACP,PVDF Coating ACP. Over the last few years, our organization is known for advanced technologies, ensuring high-quality to excellence. We are eager to cooperate with foreign companies which care much on the high quality solutions, competitive prices, strict quality control and high level service. Our aluminum plastic panels will supply to many countries and areas, including Southeast Asia, South Africa, Mexico, Australia, etc. As a reliable and professional company, Yaret partners with skilled tech teams and offers the best solutions as well as aluminum plastic panels all over the world. We look ahead for your cooperation sincerely. Please contact us. Since the factory founded, we have committed to the development of new products, we stick to the operating principle of credit first, putting you first is our mission. Our production process upholds the highest standards, we are open to discuss on product improvements and customization is possible all products have passed professional certification.

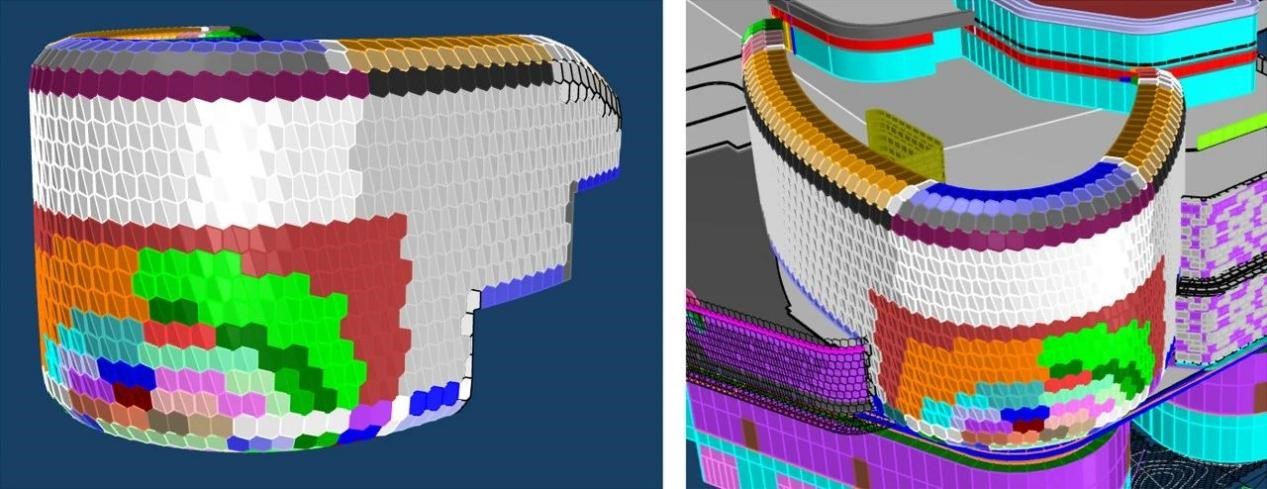

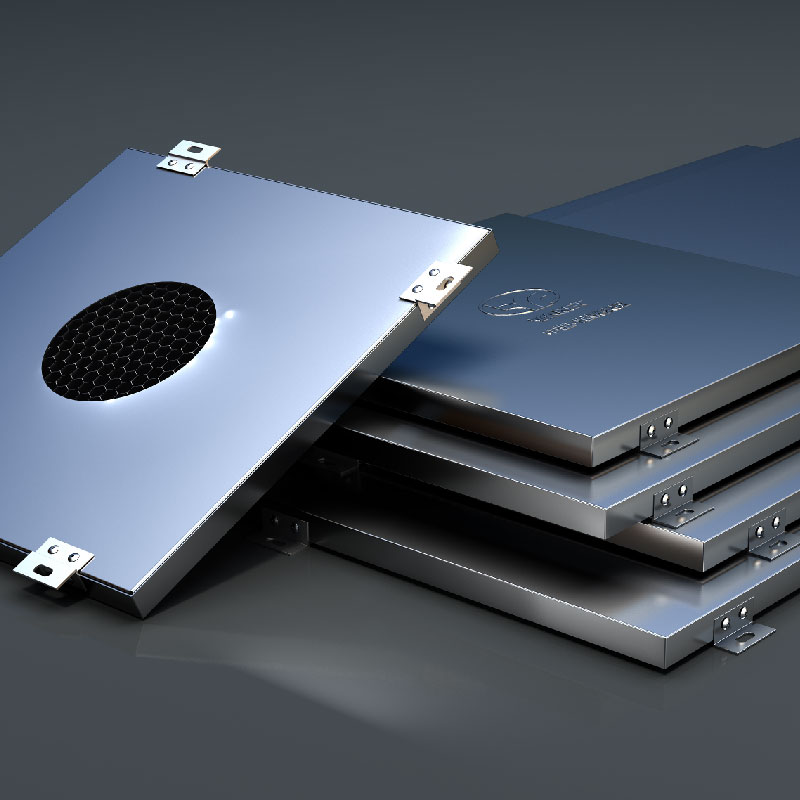

Aluminum plastic panels, often referred to as composite panels, represent a remarkable fusion of lightweight construction and superior durability, making them a favored choice in contemporary architecture and industrial applications. Comprising two layers of aluminum enclosing a non-aluminum core—typically composed of polyethylene or other materials—these panels are renowned for their exceptional rigidity and resistance to environmental stressors. The temper of the aluminum plays a pivotal role in dictating the panel’s mechanical properties, where variations such as H14 or H24 designate differing levels of strength and malleability.

These panels not only offer aesthetic versatility, available in a plethora of finishes and colors, but also exhibit remarkable thermal insulation properties and resistance to corrosion. Their inherent lightweight nature simplifies the installation process, reducing structural loads while allowing for innovative design possibilities. The combination of functionality and elegance has led to their widespread adoption across various sectors, including commercial buildings, signage, and interior applications, showcasing a commitment to both performance and visual appeal.