- 1555 Shanghai Road, Economic and Technological Development Zone, Suqian City, Jiangsu Province

- sales@yaret.com.cn

- +86 0527-80516888

Discover aluminum sheet manufacturing from yaret – quality and style combined! yaret, offering reliable aluminum sheet manufacturing with plenty yrs experience. the best aluminum sheet manufacturing!

Discover aluminum sheet manufacturing from yaret – quality and style combined! yaret, offering reliable aluminum sheet manufacturing with plenty yrs experience. the best aluminum sheet manufacturing!

Don’t miss out on Yaret’s exclusive High-quality aluminum sheet manufacturing. Yaret has top quality aluminum sheet manufacturing worth considering if you need aluminum sheet manufacturing.

Our clientele spans the globe as we provide worth purchasing aluminum sheet manufacturing to customers worldwide.

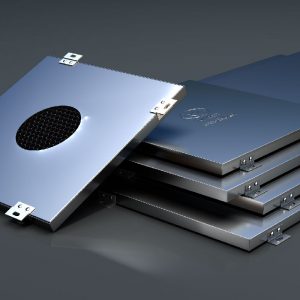

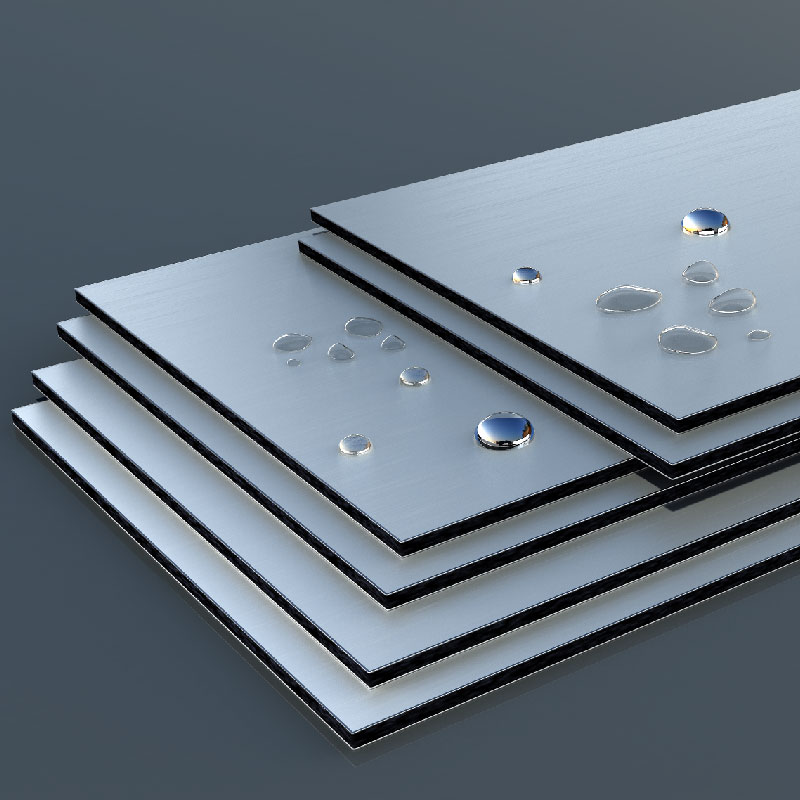

Our unparralleled are renowned for their premium quality, resilience, and ease of upkeep. Delve into our website for comprehensive information.

24/7 high-quality options to meet your needs anytime, anywhere.

Covering the entire process from raw material procurement, production and manufacturing to sales and service

Customer-oriented, pursuit of excellence, and meeting diverse needs.

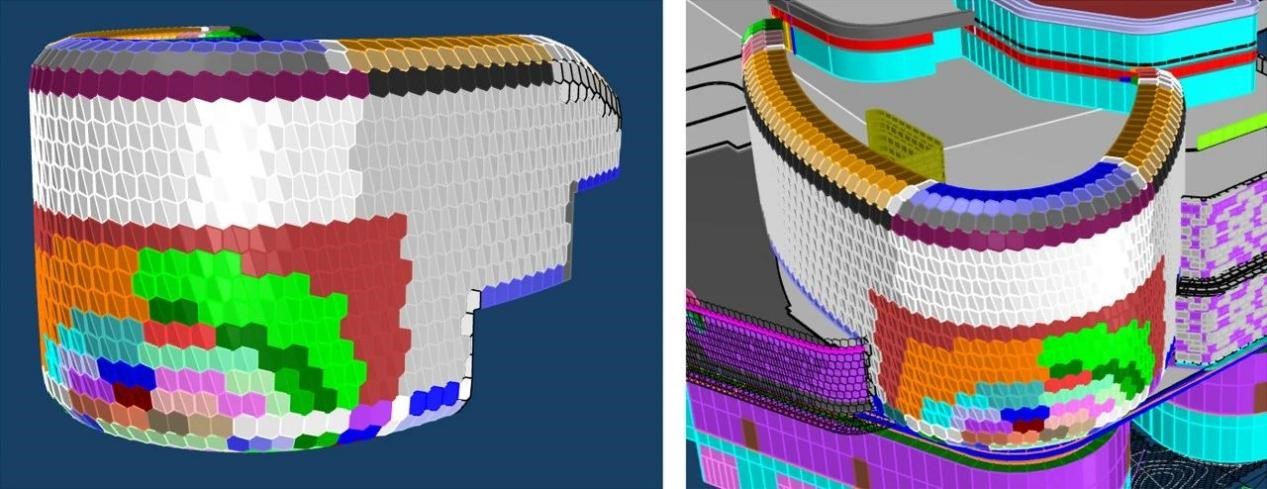

The main processes include melting aluminum, casting, rolling, and finishing. The aluminum is first melted and then cast into large slabs or sheets, which are subsequently rolled to the desired thickness and undergo surface treatment for finishing.

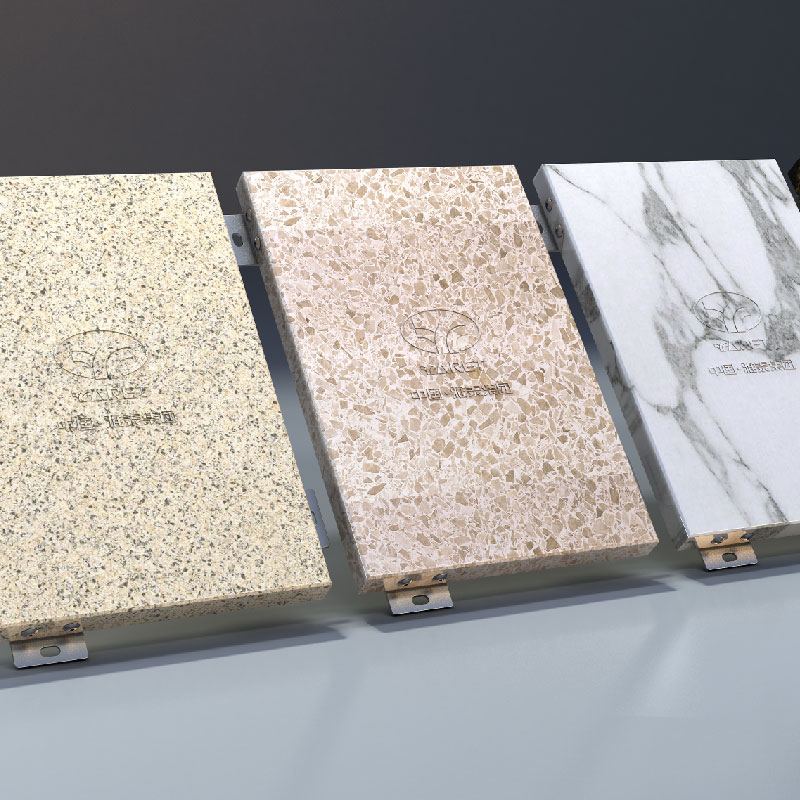

Aluminum sheets are widely used in various industries, including automotive, aerospace, construction, packaging, and electronics due to their lightweight, corrosion resistance, and malleability.

Thicker aluminum sheets tend to have greater strength and durability, making them suitable for structural applications, while thinner sheets are often used for applications requiring flexibility and formability.

Aluminum sheet manufacturing can have environmental impacts, such as energy consumption and greenhouse gas emissions. However, recycling aluminum significantly reduces these impacts, as recycled aluminum requires only about 5% of the energy needed to produce new aluminum from ore.

Explore how Yaret enhances your understanding of aluminum sheet manufacturing through cutting-edge solutions and expert knowledge.

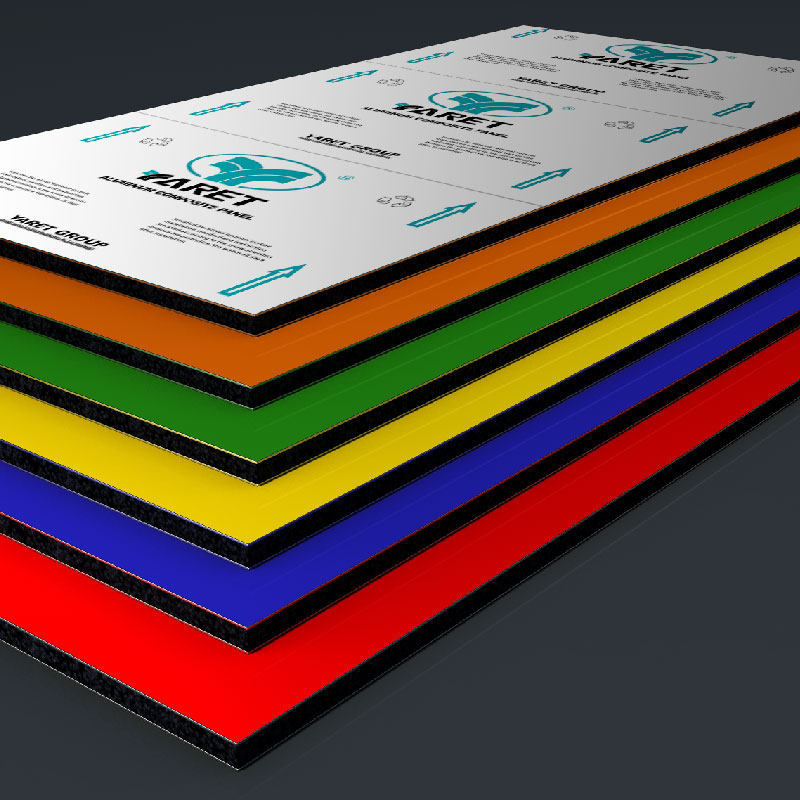

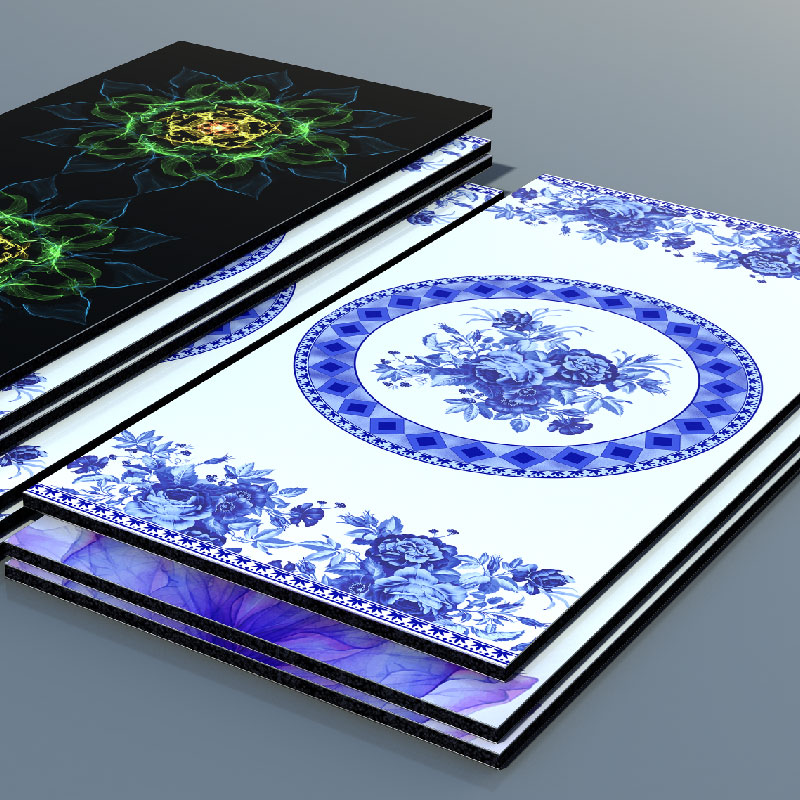

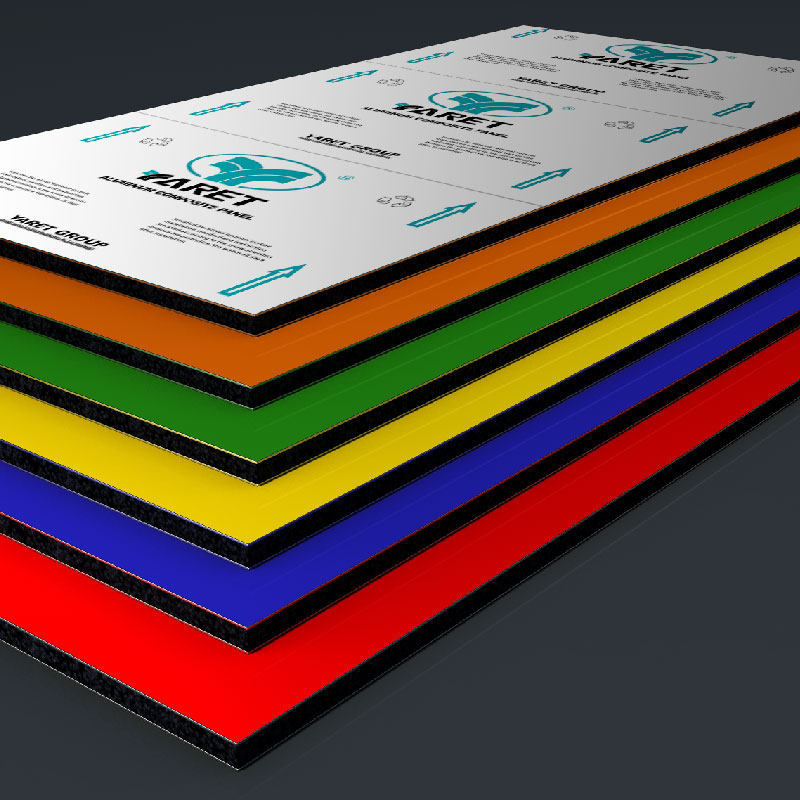

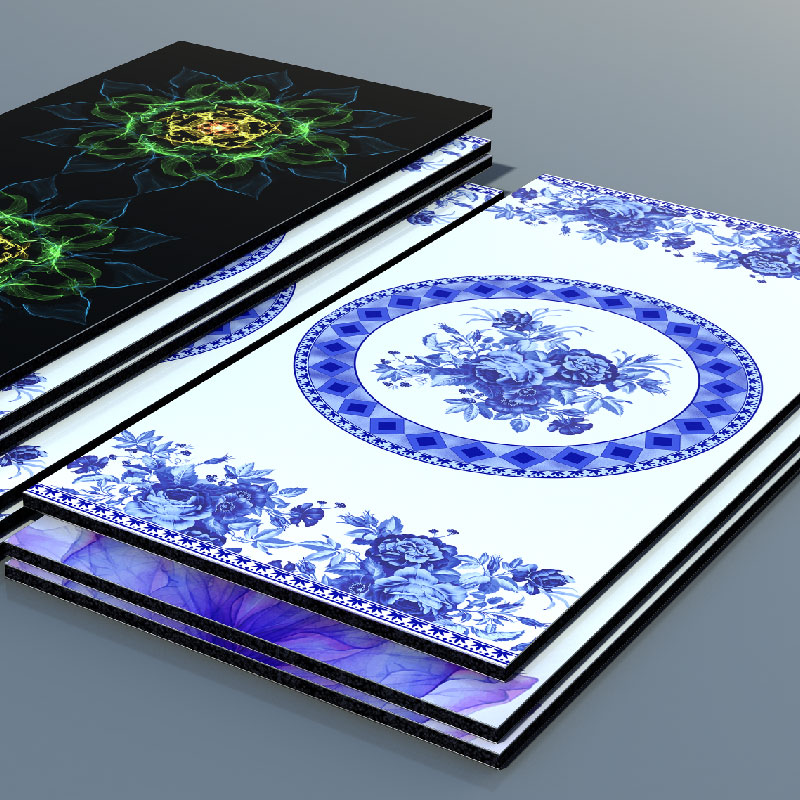

Now, with the social and economic pace, we’ve got decided to reach a broader audience. The aluminum sheet manufacturing will supply to all over the world, such as West Asia, West Africa, Canada, New Zealand, etc. Our production process upholds the highest standards, we are open to discuss on product improvements and customization is possible all products have passed professional certification. Yaret has already had a lot of top factories and qualified technology teams in China, offering the best aluminum sheet manufacturing and services to worldwide customers. We strongly think that we will do superior and far better. If you are interested in any of our products, please feel free to contact us. Through recent years, our factory is marked by integrated advanced technologies, delivering excellence. We will continually strive to improve our service, skilled operation is our work, customer first, quality excellent. We are looking forward to cooperating with you and providing our best services for you, as well as our aluminum sheet manufacturing, Brushed Finish ACP,PVDF Coating ACP.

Aluminum sheet manufacturing is a fascinating process that combines science and artistry. It all starts with raw aluminum, which is extracted from bauxite ore using a series of chemical processes. Once we have our aluminum, it’s melted down and poured into molds to create large slabs called ingots. These ingots are then heated and rolled into thin sheets through a series of giant rollers that apply massive pressure. The result is a versatile, lightweight material that’s perfect for everything from airplane wings to kitchen foil!

Then comes the fun part: tempering! This step involves heating and cooling the sheets in specific ways to enhance their strength and flexibility, making them suitable for various applications. Different tempers can produce sheets that are soft and malleable or hard and stiff, depending on what you need. With aluminum sheets, you’ve got a material that’s not just practical but also endlessly adaptable—perfect for innovative designers and makers alike!