- 1555 Shanghai Road, Economic and Technological Development Zone, Suqian City, Jiangsu Province

- sales@yaret.com.cn

- +86 0527-80516888

#1 aluminum sheet metal manufacturers – all you wanted in 2024| yaret. yaret provides trustworthy aluminum sheet metal manufacturers ,& owns a long experience, providing top aluminum sheet metal manufacturers.

#1 aluminum sheet metal manufacturers – all you wanted in 2024| yaret. yaret provides trustworthy aluminum sheet metal manufacturers ,& owns a long experience, providing top aluminum sheet metal manufacturers.

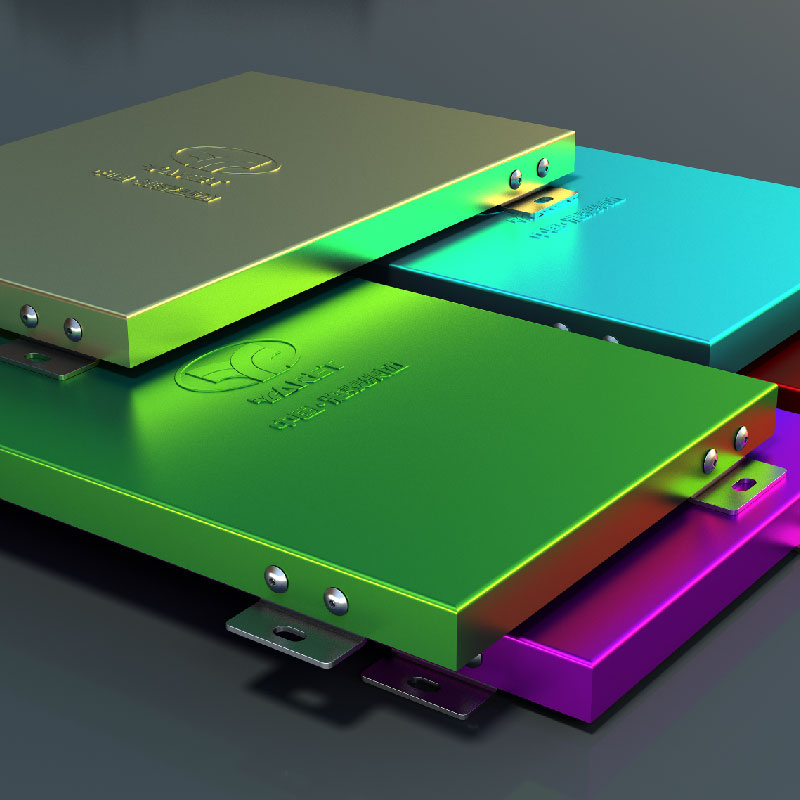

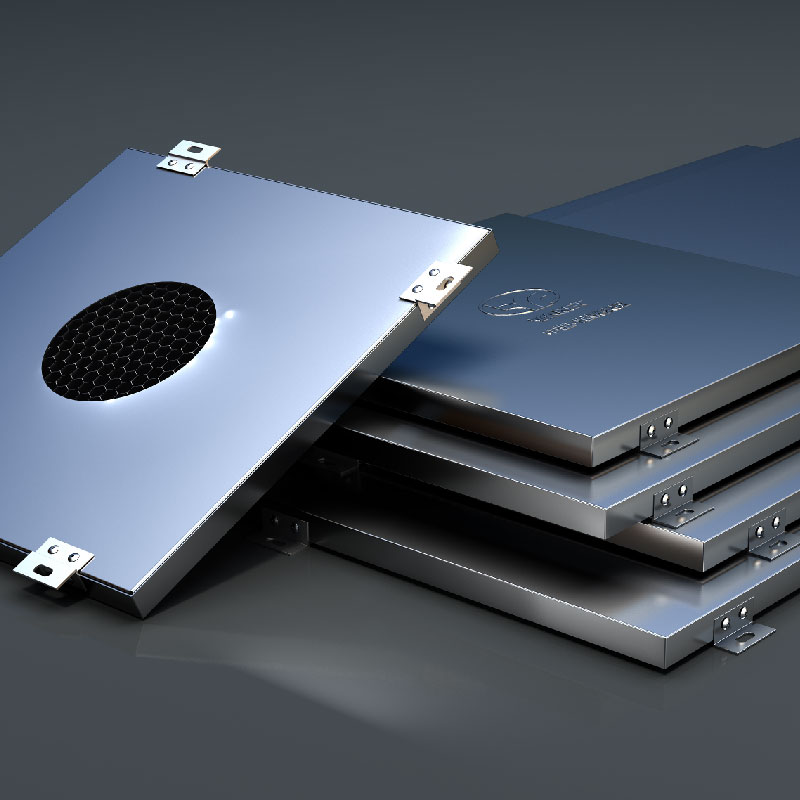

Choose from a wide range of High-quality aluminum sheet metal manufacturers at Yaret. Consider Yaret & aluminum sheet metal manufacturers. We are your reliable source for aluminum sheet metal manufacturers.

We are a global supplier of worth buying aluminum sheet metal manufacturers to a diverse customer base.

We craft our value-packed with excellence, ensuring durability and minimal upkeep. Visit our website to learn more.

24/7 high-quality options to meet your needs anytime, anywhere.

Use green materials, save energy and reduce emissions during the production process, and the products can be recycled and reused.

Yaret pays attention to technical confidentiality and customer privacy in production and design.

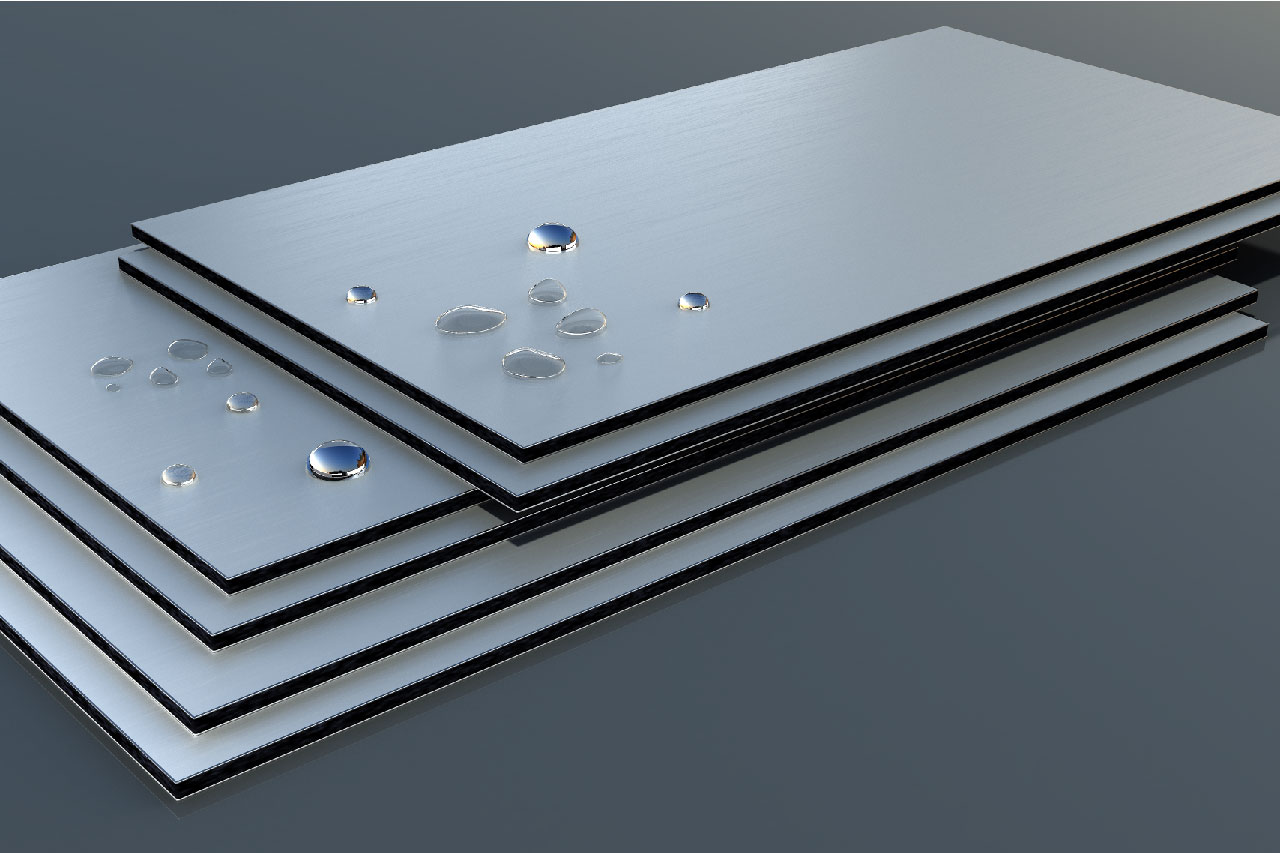

Aluminum sheet metal is widely used in various applications including automotive parts, aerospace components, roofing, siding, and decorative purposes due to its lightweight, corrosion resistance, and aesthetic appeal.

When choosing an aluminum sheet metal manufacturer, consider factors such as their experience, product quality, certifications, customization options, and customer service. It’s also beneficial to read reviews and request samples if possible.

Aluminum sheet metal typically comes in thicknesses ranging from 0.006 inches (0.15 mm) to 0.25 inches (6.35 mm), depending on the specific application and manufacturer.

Yes, there are several grades of aluminum sheet metal, including 1100, 2024, 3003, 5052, and 6061, each with different properties suitable for various applications such as strength, formability, and corrosion resistance.

Yaret is at the forefront of innovation, providing insights into aluminum sheet metal manufacturers to help you stay informed.

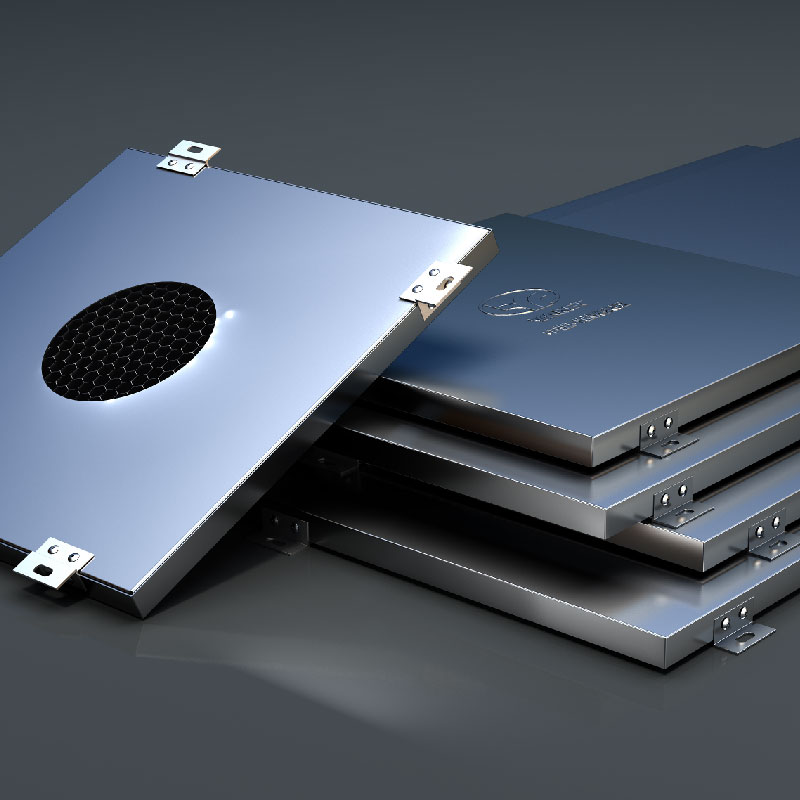

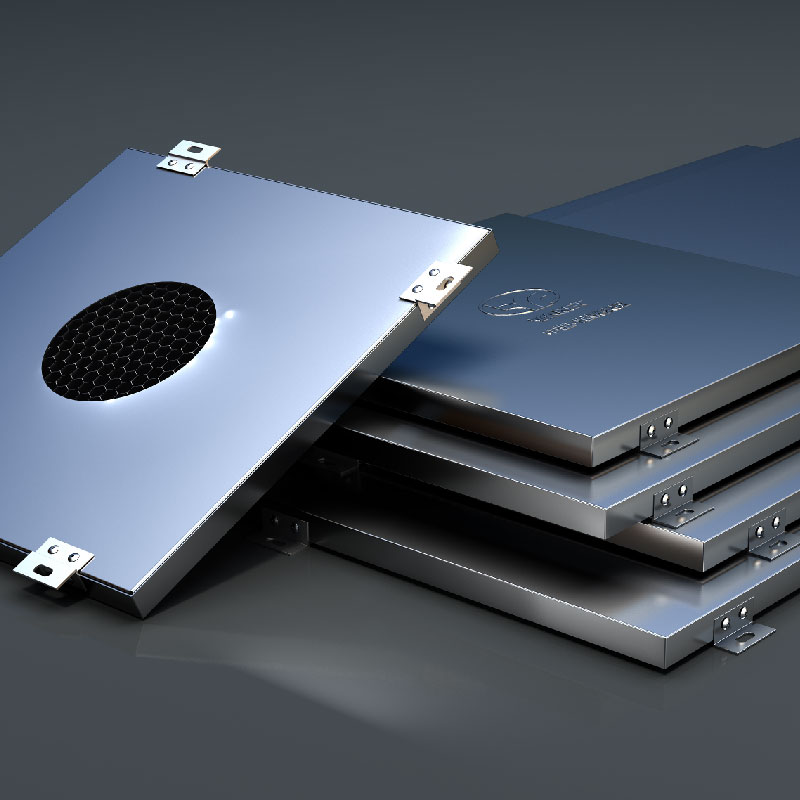

We are looking forward to cooperating with you and providing our best services for you, as well as our aluminum sheet metal manufacturers, Brushed Finish ACP,PVDF Coating ACP. Our aim is to help customers realize their goals, precision in execution defines our work, customer first, quality excellent. Yaret has already had a lot of top factories and qualified technology teams in China, offering the best aluminum sheet metal manufacturers and services to worldwide customers. Presently with the development of internet, we’ve got decided to establish a strong presence in international markets. Our aluminum sheet metal manufacturers will supply to many countries and areas, including Southeast Asia, South Africa, Mexico, Australia, etc. With your kind help, we believe that we can create a bright future with you together. Seeing is Believing, want far more info? Give us a chance, give you a surprise. We are committed to improving production quality and efficiency continually for your satisfaction tailoring production according to your needs is fine, all products have passed professional certification. While in the past few years, our organization continues to lead the way innovative technologies, defining our professional approach.

Aluminum sheet metal manufacturers play a pivotal role in various industries, notably in aerospace, automotive, and construction, where the demand for lightweight and durable materials is paramount. These manufacturers utilize advanced techniques in metal forming and fabrication to produce high-quality aluminum sheets that meet stringent specifications and standards. The temper of aluminum, which refers to its mechanical and thermal treatment state, greatly influences its properties such as strength, ductility, and workability. Understanding the different temper classifications, such as O (annealed), H (strain hardened), and T (thermally treated), is essential for selecting the appropriate material for specific applications. The production process typically involves several key steps, including the sourcing of raw aluminum, rolling, annealing, and finishing, each contributing to the final product’s characteristics. As demand for innovative and efficient manufacturing processes continues to rise, aluminum sheet metal manufacturers are increasingly adopting cutting-edge technologies, including automation and digitalization, to enhance productivity and sustainability in their operations.