- 1555 Shanghai Road, Economic and Technological Development Zone, Suqian City, Jiangsu Province

- sales@yaret.com.cn

- +86 0527-80516888

#1 coil manufacture – all you wanted in 2024| yaret. discover yaret! we provide reliable coil manufacture ,& engaged in coil manufacture market for many yrs.

#1 coil manufacture – all you wanted in 2024| yaret. discover yaret! we provide reliable coil manufacture ,& engaged in coil manufacture market for many yrs.

Yaret brings you an impressive array of High-quality coil manufacture. Consider Yaret & coil manufacture. We are your reliable source for coil manufacture.

We cater to a diverse international customer base with our unique coil manufacture.

The unparralleled we offer are synonymous with high quality, longevity, and effortless maintenance. Check out our website for extensive details.

Make production processes transparent, ensure quality control, information traceability, and enhance customer trust

Yaret pays attention to technical confidentiality and customer privacy in production and design.

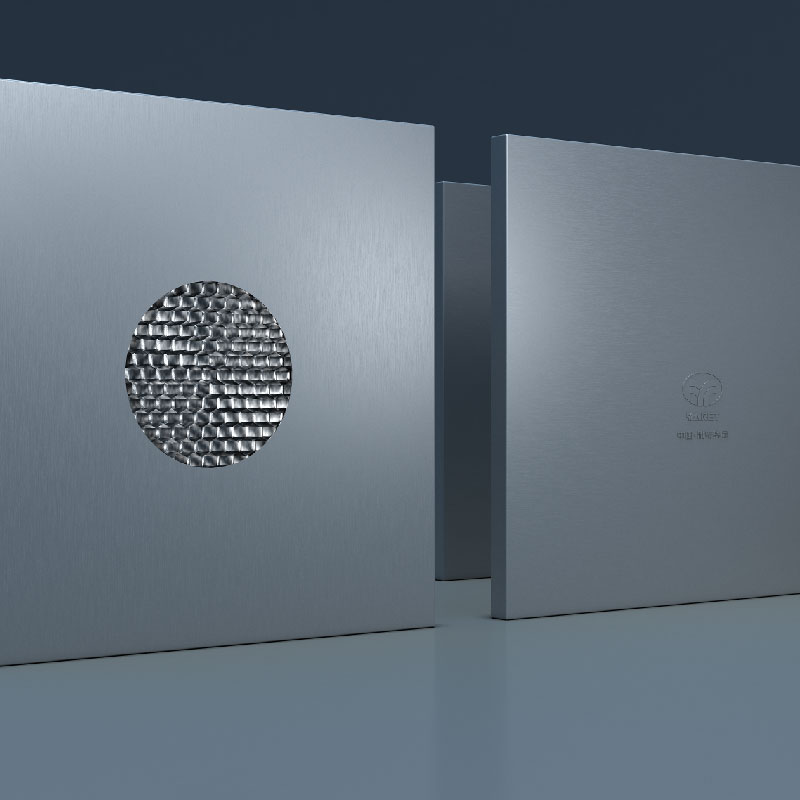

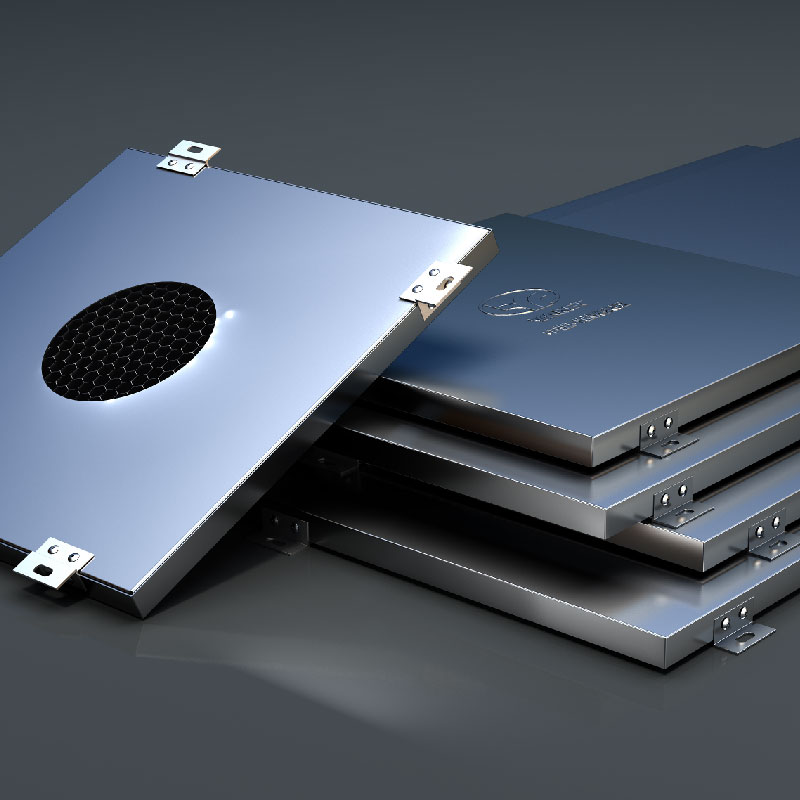

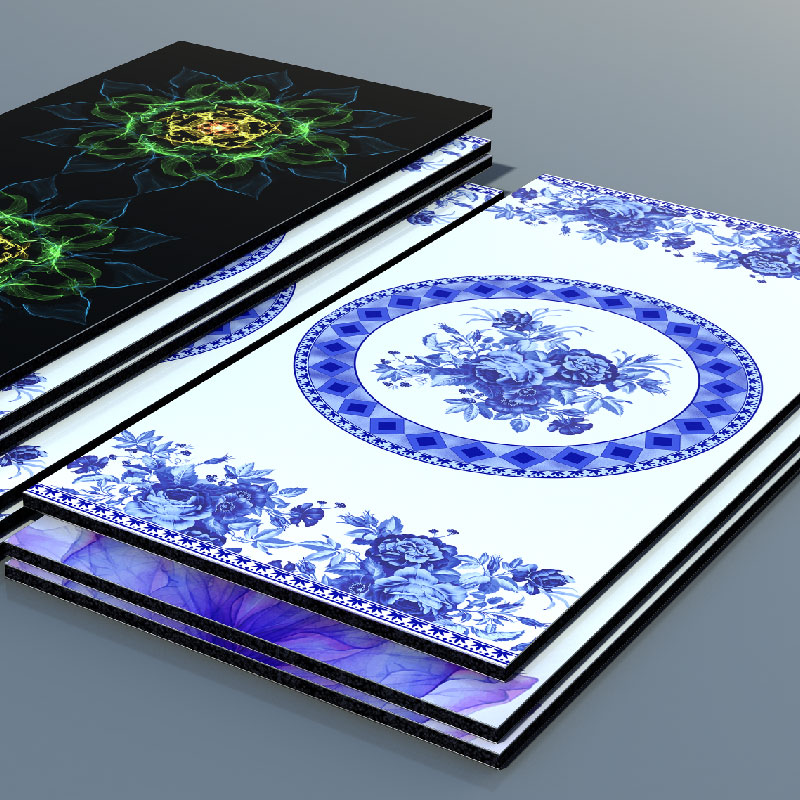

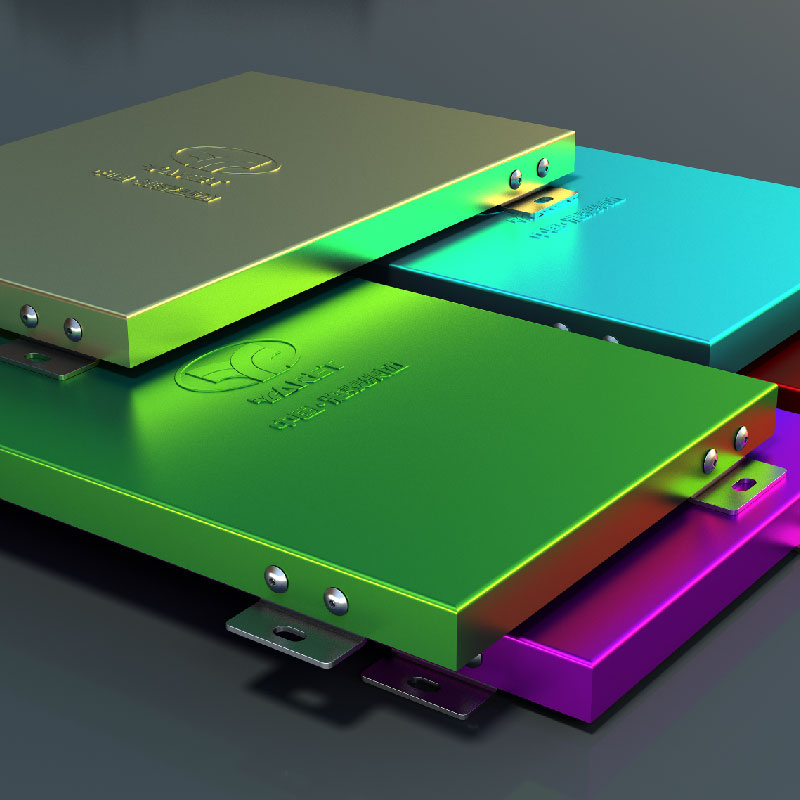

With its excellent quality, innovative design and wide range of applications, it has won high recognition from the market and trust from customers.

The main types of coils manufactured include solenoid coils, induction coils, transformer coils, and heating coils, each serving different applications in electrical and electronic systems.

Common materials used in coil manufacture include copper wire for winding, aluminum wire, and insulating materials like enamel or plastic coatings to prevent short circuits.

The manufacturing process of coils generally involves winding conductive wire around a core, applying insulation, and then testing for electrical properties and performance before final assembly.

Manufactured coils are utilized in various applications, including motors, transformers, inductors, relays, and heating elements, playing a crucial role in electrical and electronic devices.

Discover how Yaret’s commitment to excellence enriches the landscape of coil manufacture for all enthusiasts.

Now, with the social and economic pace, we’ve got decided to reach a broader audience. We supply our coil manufacture worldwide, with markets including South Asia, North Africa, United States, Western Europe, etc. Good quality would be the key factor to the company to stand out from other competitors, innovation is our soul and spirit, customers’ satisfaction is our future! Our production process upholds the highest standards, we are open to discuss on product improvements and customization is possible all products have passed professional certification. We are looking forward to cooperating with you and providing our best services for you, as well as our coil manufacture, Digital printing ACP,PE Coating ACP. We strongly think that we will do superior and far better. If you are interested in any of our products, please feel free to contact us. Yaret collaborates with many factories and qualitified team to provide expert and affordable coil manufacture worldwide. While in the past few years, our organization continues to lead the way innovative technologies, defining our professional approach.

Coil manufacturing is a crucial process in various industries, serving as the backbone for the production of electrical components, appliances, and automotive parts. This process involves creating coils from various materials such as copper, aluminum, and steel, which are then shaped and tempered to achieve specific mechanical properties. The tempering process is practical for enhancing the ductility, strength, and overall performance of the coils, making them suitable for their intended applications. By employing rapid prototyping techniques, manufacturers can efficiently design and test new coil configurations, allowing for quicker iterations and innovation. This not only streamlines production but also ensures that the final product meets the rigorous demands of modern engineering standards.