- 1555 Shanghai Road, Economic and Technological Development Zone, Suqian City, Jiangsu Province

- sales@yaret.com.cn

- +86 0527-80516888

#1 honeycomb sandwich panel manufacturers from yaret | china manufacturer | fast delivery. yaret, providing reliable honeycomb sandwich panel manufacturers , owning many yrs experience, offers the best honeycomb sandwich panel manufacturers.

#1 honeycomb sandwich panel manufacturers from yaret | china manufacturer | fast delivery. yaret, providing reliable honeycomb sandwich panel manufacturers , owning many yrs experience, offers the best honeycomb sandwich panel manufacturers.

Choose from a wide range of High-quality honeycomb sandwich panel manufacturers at Yaret. Trust Yaret & their honeycomb sandwich panel manufacturers when you’re seeking honeycomb sandwich panel manufacturers.

We have a strong international presence, delivering high-quality honeycomb sandwich panel manufacturers to customers globally.

You can expect our not to be missed to be top-quality, long-lasting, and straightforward to maintain. Learn more by visiting our website.

Make production processes transparent, ensure quality control, information traceability, and enhance customer trust

Good compactness, high density, high hardness, strong resistance to high pressure, high temperature, corrosion and wear.

Customer-oriented, pursuit of excellence, and meeting diverse needs.

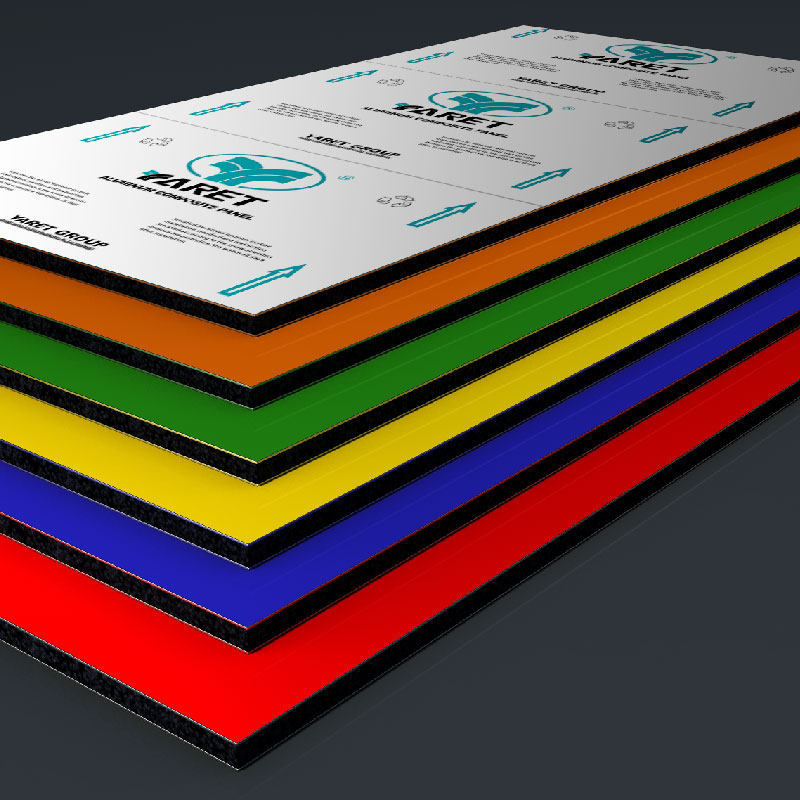

Honeycomb sandwich panels are composite materials consisting of two thin face sheets and a lightweight honeycomb core, providing high strength-to-weight ratios ideal for various applications in construction, transportation, and aerospace.

Some leading manufacturers include Armacell, 3A Composites, and Hexcel, known for their innovative designs and high-quality products in the honeycomb sandwich panel market.

Honeycomb sandwich panels are commonly used in the aerospace, automotive, construction, and marine industries due to their lightweight and high-strength properties.

To choose the right manufacturer, consider factors such as product quality, customization options, industry experience, customer reviews, and compliance with relevant standards and certifications.

With a focus on honeycomb sandwich panel manufacturers, Yaret offers comprehensive resources to deepen your understanding and application.

Yaret has already had a lot of top factories and qualified technology teams in China, offering the best honeycomb sandwich panel manufacturers and services to worldwide customers. Now, with the desire to expand our business, we’ve got decided to extend business to overseas market. The honeycomb sandwich panel manufacturers will supply to all over the world, such as West Asia, West Africa, Canada, New Zealand, etc. We’re seeking forward for your inquiries. For additional parameters and item list details, please contact us to acquire additional information. Our experienced R&D team is here to provide you with professional support, all customized orders are acceptable, we ensure that every product meets the criteria for professional certification. Over the last few years, our organization is known for advanced technologies, ensuring high-quality to excellence. We are looking forward to cooperating with you and providing our best services for you, as well as our honeycomb sandwich panel manufacturers, Brushed Finish ACP,PVDF Coating ACP. With a strong team of experienced engineers in hose design and development, we value every opportunity, innovation and integrity guide our path, we adhere to honesty and superior faith working attitude.

Honeycomb sandwich panels have emerged as a pivotal solution in various industries, offering a unique combination of lightweight construction and exceptional structural integrity. Manufacturers in this field specialize in creating these innovative materials by sandwiching a core structure—typically honeycombed—between two outer layers made from materials like aluminum, fiberglass, or composite materials. This interdisciplinary approach merges principles from aerospace, civil engineering, and materials science, resulting in panels that enhance performance while reducing weight. The versatility of honeycomb sandwich panels makes them ideal for applications in aviation, automotive, and even architectural sectors, reflecting a growing trend towards efficiency and sustainability in design and manufacturing. As the demand for advanced materials continues to rise, honeycomb sandwich panel manufacturers play a crucial role in driving innovation and delivering high-quality products that meet the evolving needs of various industries.